Welcome to CleanTech Processing

Over xxxxxxx tyres are scrapped every year in Ireland, according to industry experts. CleanTech is the first company in Ireland to offer a complete, environmentally sound solution to the challenge of recycling end of life tyres. Our unique and patented system returns the tyre to its component parts; oil, carbon, gas and steel.

Headquartered in Trim, County Meath, CleanTech is the only company in Ireland to have secured the necessary planning and permit permission to undertake the engineering solution known as Thermolysis.

About Us

CleanTech Processing Group is an indigenous Irish company, established to eliminate the problem of disposal of end of life tyres. Our unique, patented technology offers a complete recycling solution, returning tyres to their original component parts.

Environment

According to industry sources, xxxxxxx tyres are disposed of in Ireland every year. At best, these tyres are collected, bundled and shipped overseas. From here, they may be dumped or incinerated, potentially causing significant environmental damage.

Technology

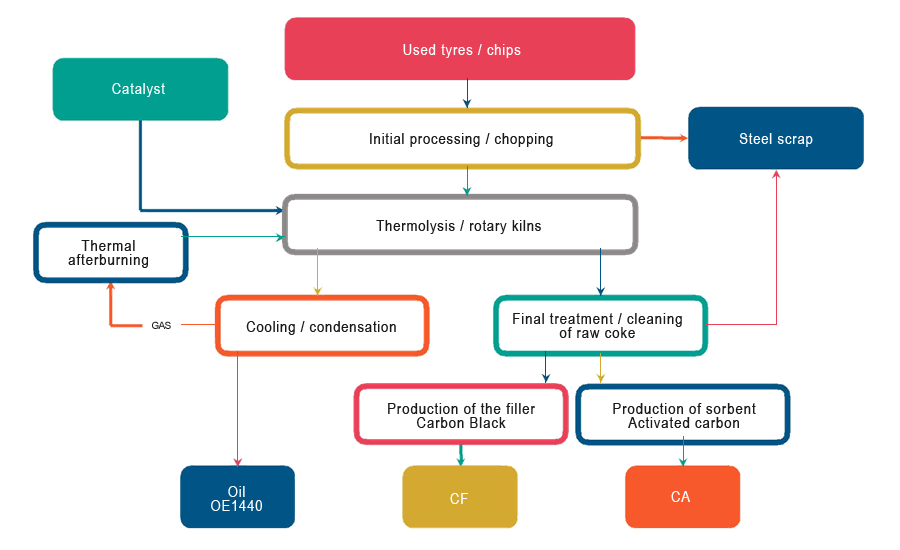

CleanTech’s technical process of disposing of rubber tyres mainly involves recovering the hydrocarbons and other components present in tyres under controlled temperature and pressure in an oxygen free chamber.

Delivering a Cleaner Environment

If tyres are not properly disposed of, they may pose risks to public health and to the environment. CleanTech delivers a complete recycling solution. Because of this, it offers the best results for the environment.

Minister Kelly Responds to Tyre Industry

“I want to be very clear about this, what the Government is proposing is quite simple, despite all of the misinformation out there. We want the tyre sector to collect, sort and manage the waste they produce in an environmentally sound manner. No more no less.”